DICOM, STL, CAD/CAM, Stereolithography, Guided Implant Surgery. Implant dentistry has a new language and it has revolutionalized how we treatment plan, place, and restore implants. Traditional implant surgery consists of the creation of a flap in the gingival tissue in order for the clinician to visualize the bone quantity and quality prior to placement of the implant and suturing. This is followed by a period of four months of healing prior to the placement of a definitive restoration. Often times a miscommunication between the surgeon and the restorative dentist results in the misplacement of the implants, resulting in difficulties in final prosthetic design.

The advent of guided implant surgery software has allowed the clinician to treatment plan the implant placement digitally based on the final prosthesis. It also led to a new language that we use in order to provide minimally invasive surgeries to our patients. Guided implant surgery is made possible by the utilization of a computer software program that allows us to import DICOM and STL files. A Digital Imaging and Communications in Medicine file (DICOM) is how we share Computed Tomography (CT) and other radiology data in medicine and dentistry. With a computer software, the DICOM file which contains radiographic images of the patient's head and neck, a three dimensional image is created.

The software also allows clinicians to import a second data set. Stereolithography (STL) files are utilized in Computer Assisted Design/Manufacturing and contain tesselations of surface topography data of a three dimentional object, in this case the patient's mouth. This data is collected from patients in two forms: an intraoral scan of the patient's mouth or the scan of the patient's stone casts made from impressions. The merging of the DICOM and STL files in the computer software is invaluable because it combines the 3D accuracy of the bone quality and quantity taken from the DICOM file and the precision of the surface topography taken from the STL file. Once merged, a prosthetic can be designed and implants can be placed precisely where the restoration is required.

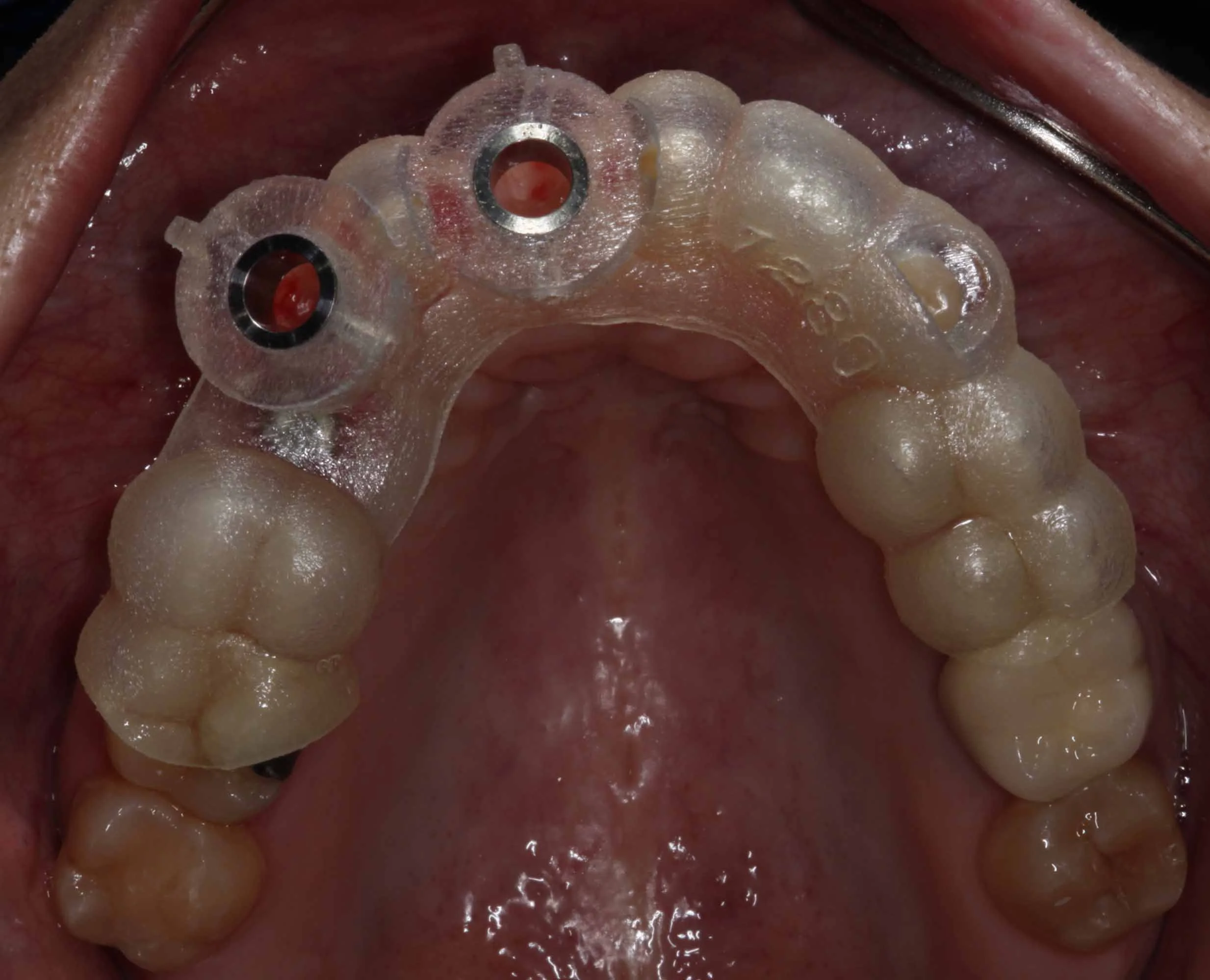

The last step is to create a file to send to a stereolithography printer for the 3D printing and fabrication of a surgical guide. Under the same software, a surgical guide can be designed to help the clinician through a seamless workflow that increases the accuracy of implant placement. Hence, the name Computer Aided Design/Computer Aided Manufacturing (CAD/CAM). The stereolithography printer also utilizes the STL language which allows the transfer of the 3D topographical information from the design of the surgical guide in the computer software to the reality of the fabrication of a physical guide. Once printed, sleeves are placed in pre-planned areas in the surgical guide which fit the drilling sequence of the guided surgery with a maximum deviation of 0.2-0.5 mm. This helps the clinician guage the location, angle, and depth of the implant, avoiding critical structures which may otherwise be damadged.

So how do I do my guided implant surgeries? The patient undergoes a comprehensive clinical and radiological examination. Once a proper treatment plan is created and accepted by the patient, an intraoral scan is taken from the patient's mouth utilizing the 3Shape Trios intraoral scanner. The file output is in an STL format which is saved on my computer. The patient also receives a Cone Beam Computed Tomography (CBCT) scan with the Prexion scanner which gives me 512 images at 0.15mm increments. Prexion's own software program puts these images together using a specific algorithm to that machine which gives me a 3D image of the pateint's bone in a DICOM format. This is also saved on my computer. Under the 3Shape Implant Studio program, the STL and DICOM files are imported and merged. A diagnostic wax up of tooth location is completed virtually. Bone quality and quantity are evaluated and implants are virtually placed. Based on where the implants are placed, a surgical guide is designed and an output in STL format is sent to the ObJet stereolithography printer and a guide is fabricated with a biocompatible material (MED610). Once printed and cleaned, a sleeve is placed into the guide which will help guide the subsequent surgical drills for the placement of implants.

The rest is easy! Predictable, accurate, efficient, and less invasive procedures for my patients. A full arch of implants can be placed after proper treatment planning in an average of one hour. Guided implant surgery and CAD/CAM technology has completely revolutionalized dentistry and the way I treat my patients. It's exciting, and has literally changed my life and the lives of my patients.